Knoll, Nicolaus & Co.

By Larry B. Schuknecht

Nicolaus Knoll-Berlin and his falling block rifle action.

Germany’s answer to the American Sharps action.

Very little is known about this talented gun maker. I have not seen anything written about him since his obituary which appeared in the Jan. 25, 1910 Der Waffenschmied, and I have never seen images of one of his rifles. Following is a Google translation of that obituary-

“Master gunsmith (Büchsenmachermeister) Nikolaus Knoll, a person well-known in Berlin gunsmiths and shooting circles, passed away on January 7th after severe suffering at the age of 64 and will be laid to rest on January 11th with numerous participants from Berlin gunsmiths and shooters. After holding the position of works leader at the court gunsmith Förster for many years, he established his own shop and later took over the administration of the shooting ranges in Köpenick, Steglitz and Schönholz. In terms of weapons technology, he achieved excellent results. He liked to use a target rifle with a vertical block that he designed and bears his name. May the earth be easy for the excellent man who served as a role model to many and who was treated with the greatest respect in professional circles because of his enormous abilities.”

Nickolaus was born in 1846 and may have served his apprenticeship in the Wilhelm Förster shop which was founded in 1861 in Berlin. It is not known when he started his own shop, an 1883 Berlin Address book gives his address as Königgrätzerstrasse 24, the first advertisement found for him dates to 1890 and gives the address as Chalottenstrasse 33. Another advertisement believed to be from around 1893 gives his shop address as Jägerstrasse 10.

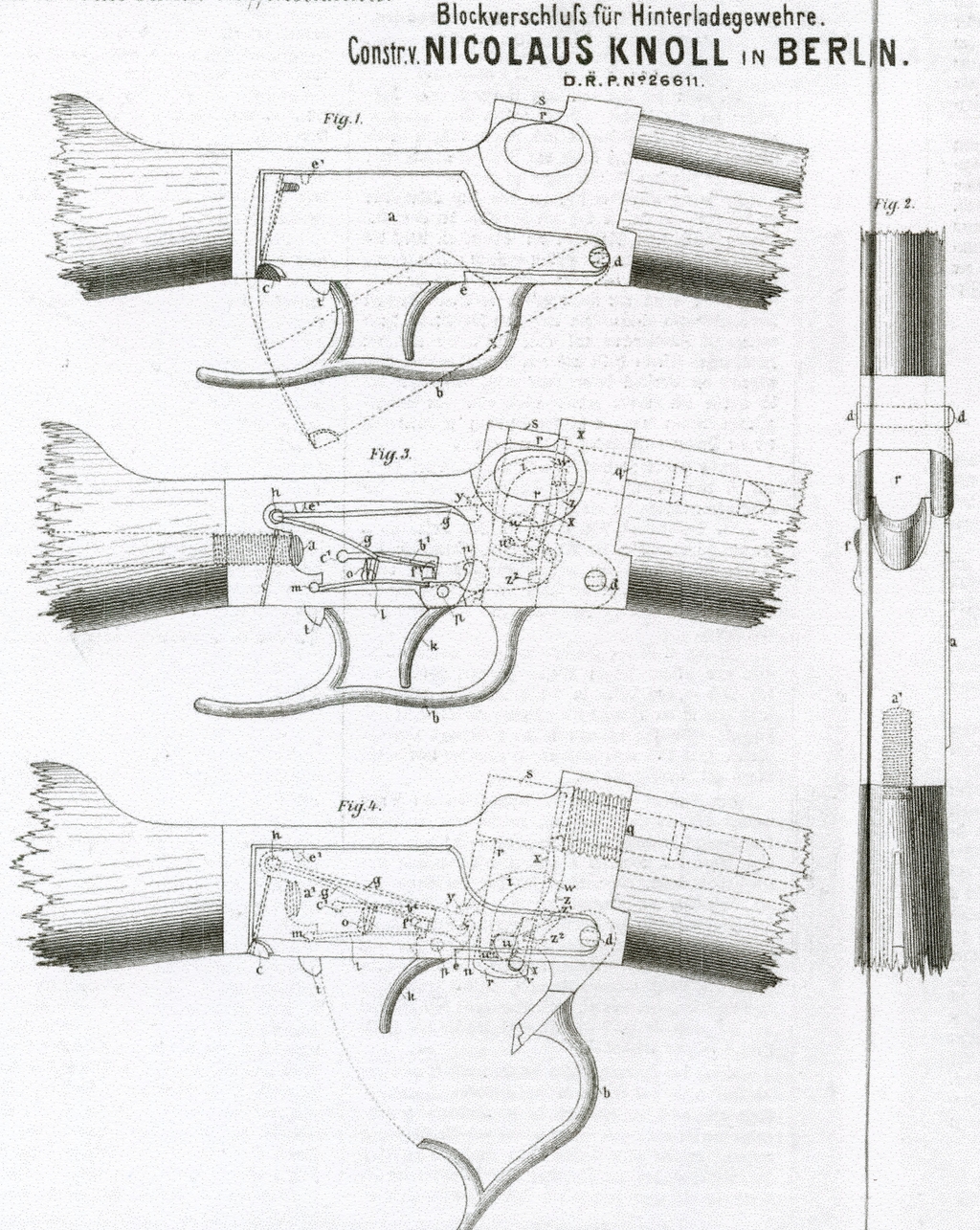

On Sept. 8, 1883 Nikolaus received the Imperial German Patent (DRP) no. 26611 for a single shot falling block action. Two articles about the rifle action appeared in the German periodicals in 1884. The first is found in the Der Waffenschmied von Suhl of May 15th. The second article appeared in the Der Waffenschmied of Munich on July 1. The second article appears below in it’s

entirety followed by a Google translation.

Nicolaus Knoll in Berlin

Breech-loading rifle with block breech

German Imperial Patent dated September 8, 1883

Against a rifle system that can be described as new.

The vertical block A is lowered by simply adjusting the lever bracket B, in which the shorter arm M of the same engages in a slot of the block, thus causing the latter to be raised or lowered in the housing with the corresponding movement. Thus, what has been repeated countless times since Sharp’s system has been reproduced once again but is particularly simple and used in a very practical manner, taking the entire construction into account.

When the lever bracket is pulled down, arm M pushes back the hammer E mounted in the sliding breech block A, a little so as not to touch the base of the cartridge. As a result of the movement of the block, the spring R resting on it is now taken along by the hammer until it falls into the catch of the trigger rod D at its outer end and is kept in tension by it. At the same time, ejector E also takes effect and the old cartridge is removed from the chamber.

By tightening the lever, the block is lifted again by the arm M and the hammer, resting loosely in the block without changing its position, is brought with its tip exactly in front of the center of the cartridge, while the mainspring is kept in tension by the trigger rod. When the trigger is pressed, the spring is released from the rest and its reinforced front-end shoots upwards, where it hits the hammer and pushes it forward against the base of the cartridge.

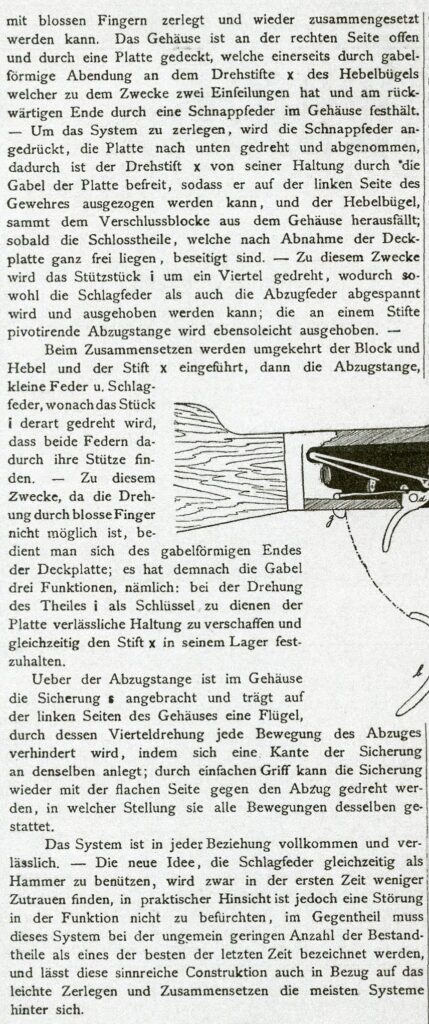

The system is built in such a way that it can be disassembled and reassembled with your bare fingers without any tools. The housing is open on the right side and covered by a plate, which on the one hand is held in the housing by a fork-shaped projection on the pivot pins If the snap spring is pressed, the plate is turned downwards and removed, the pivot pin falls out; as soon as the lock parts, which are completely exposed after the cover plate has been removed, have been removed. – For this purpose, the support piece I is twisted by a quarter, whereby both the striker spring and the trigger spring are tensioned and can be lifted out; the one pivoting on a pin The trigger bar is lifted out just as easily. – When assembling, the block and lever and the pin – For this purpose, since rotation with bare fingers is not possible, use the forked end of the cover plate; The fork therefore has three functions, namely: to serve as a bowl ? during the rotation of part I, to provide a reliable position for the plate and at the same time to hold the pin X in its bearing.

The safety G is mounted in the housing above the trigger rod and has a wing on the left side of the housing, the quarter turn of which prevents any movement of the trigger by resting one edge of the safety against it; With a simple grip, the safety can be turned again with the flat side against the trigger, in which position it allows movements of the trigger.

The system is perfect and reliable in every respect. – The new idea of using the mainspring at the same time as a hammer will initially find less confidence, but from a practical point of view there is no fear of a disruption in its function. On the contrary, this system finds advantage as one due to the extremely small number of components and can be described as one of the best of recent times, and this ingenious construction also leaves most systems behind in terms of easy disassembly and assembly.

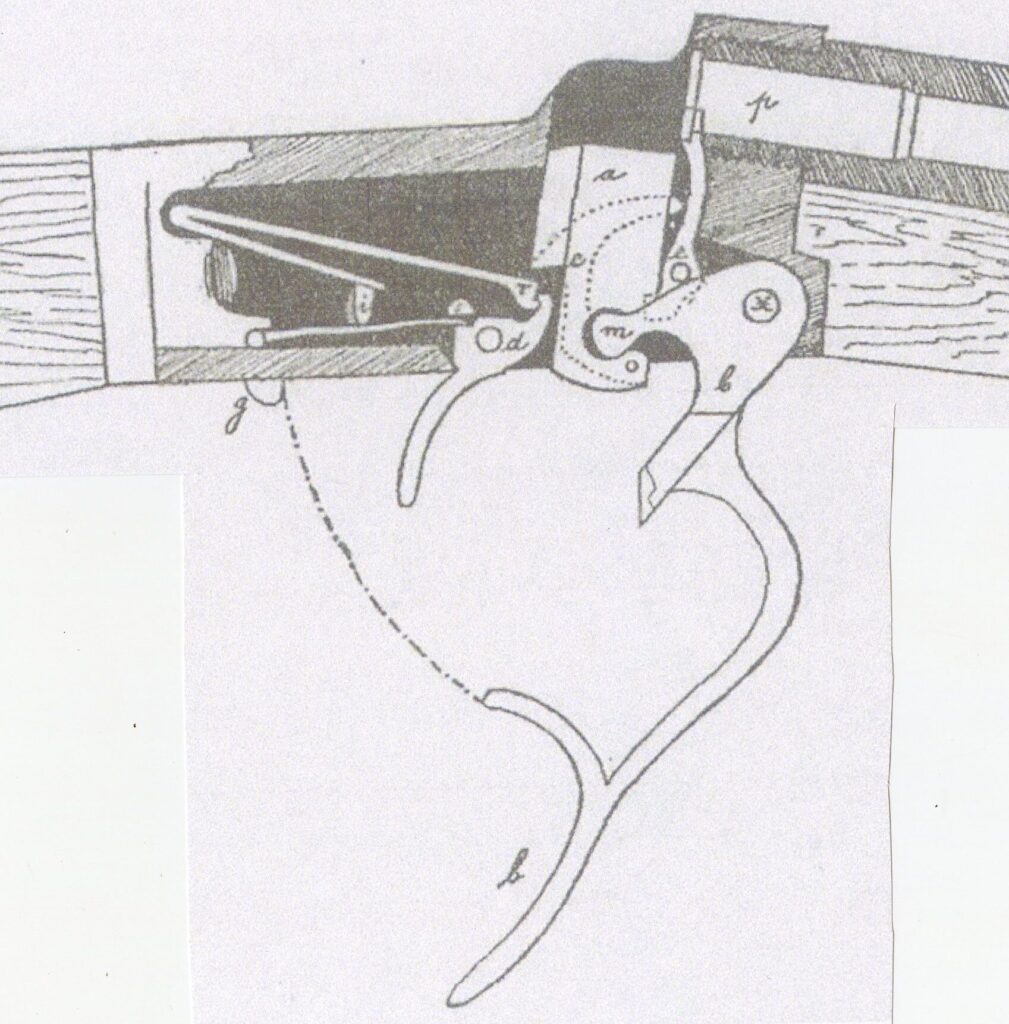

On the following page is the illustration of the action from the Der Waffenschmied- Munich article which shows the side plate and outside features.

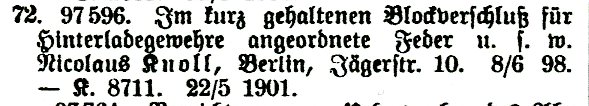

Nicolaus Knoll of Jagerstrasse 10, Berlin was issued DRGM no. 97596 on May 22, 1901. A Google translation of the DRGM reads as “In the briefly held block closure for rear loading rifles arranged spring”.