Ern, Max

Max Ern, Master Gunmaker

Evelyn Ern, Gun Engraver

Max Ern Jr. Master Gunmaker

Berg. Landstrasse 87

D-51375 Leverkusen-Schlebusch

Germany

Tel. 49-214-53068

Email: [email protected]

Website: www.max-ern.com

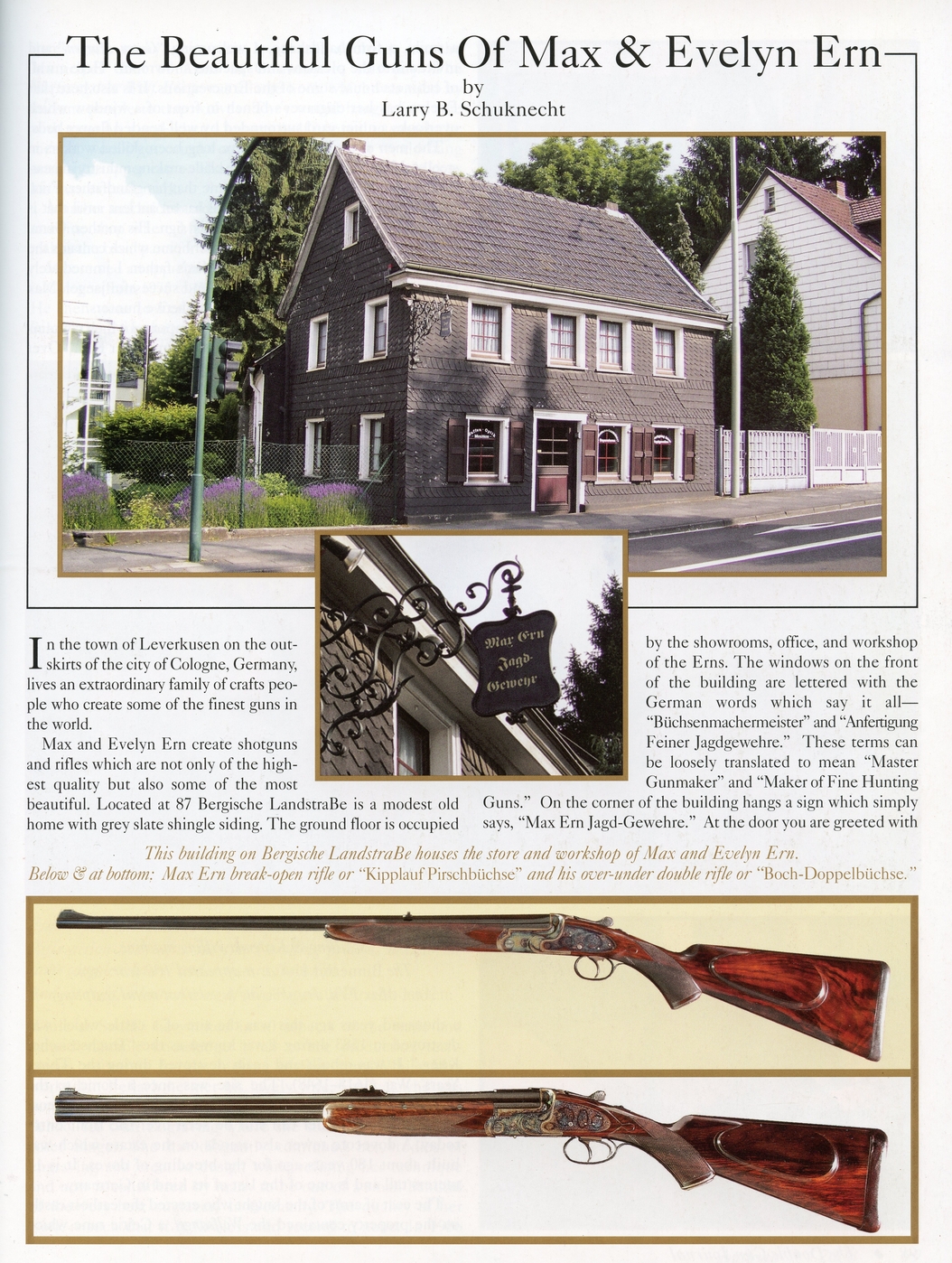

Outstanding quality, perfection in performance and handling, are the characteristic features of the handmade guns from the workshop of Max Ern. Traditional well established practices are combined with technical innovation and modern methods and developments. Tip up rifles, over and under rifles and side by side rifle as well as repeating rifles are made to perfection, meeting the unique individual demands of each client. Their slender appearance meets the highest aesthetic expectations.

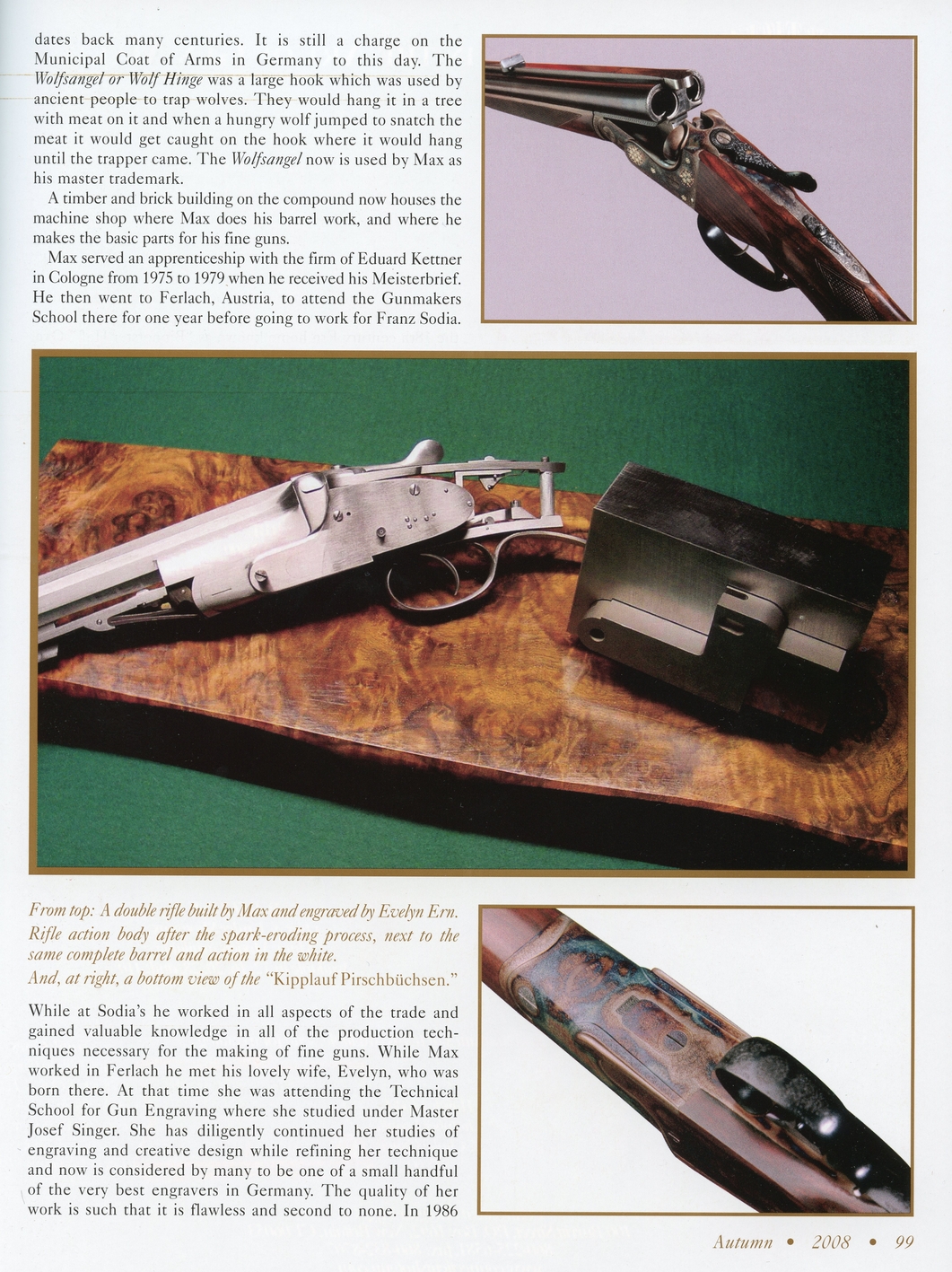

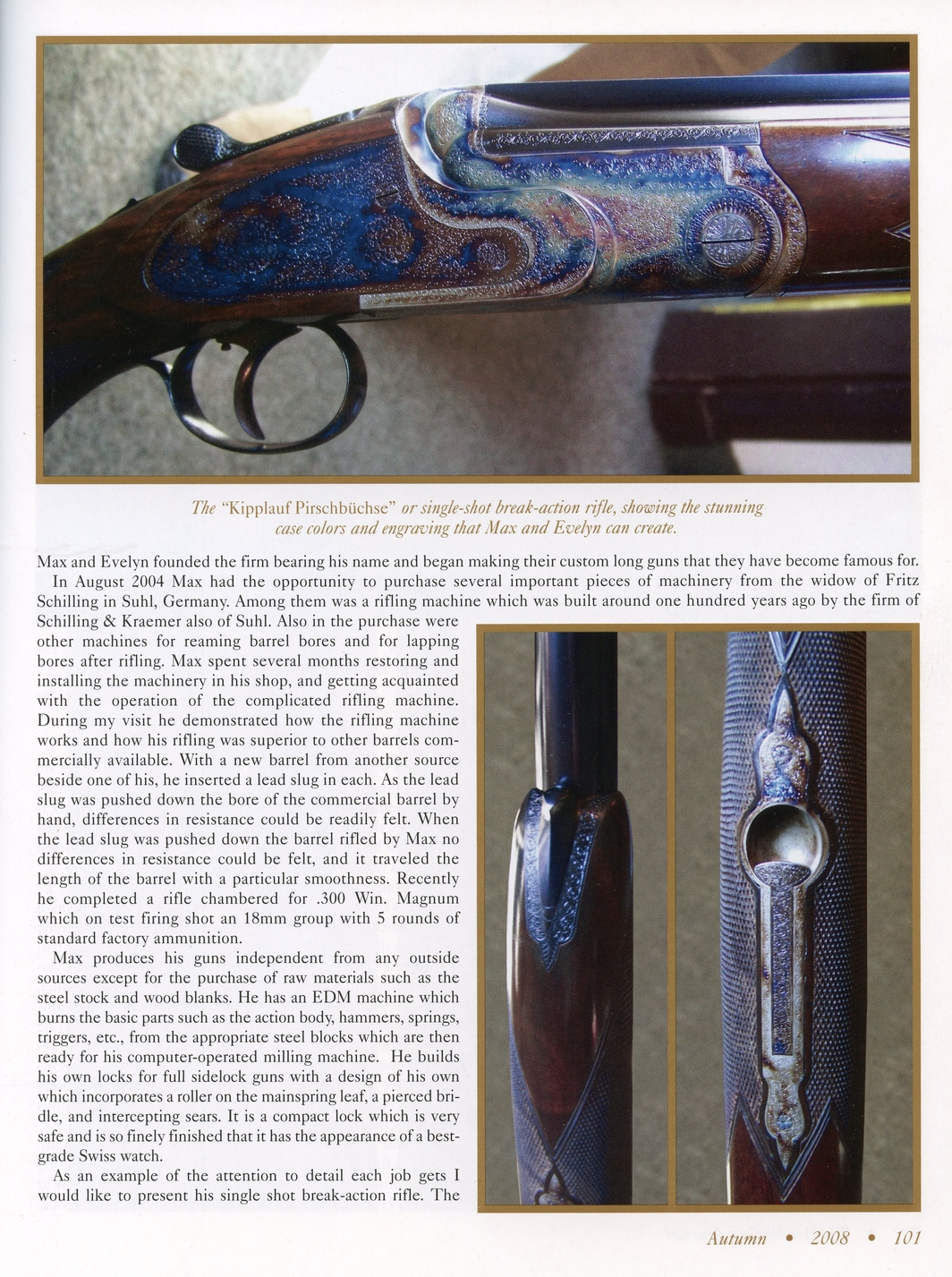

Being able to work quickly and independently, all important row blanks are made in the workshop of Max Ern. He is one of the few German gun makers in whose own rifling shop, barrels with minimum tolerances are made. The core of a rifle is the frame and locks with breeches. The usual frames are too big and too square for the slim silhouette of the rifles Max Ern creates. The demands for perfect function and the pleasing and aesthetics look of a finished rifle gave him reason to use a mostly forgotten third fastener with a rising bite. It is much more difficult to make but much more pleasing in a appearance and just as stront as the Kersten bolting system, also called double Greener, but can only be made by excellent craftsmen. The anatomy of the client is the basis for dimensions and the shape of the stock; it must fit like a glove. The artistic perfection of a rifle created by Max Ern and his son Max Ern Junior is enhanced by the engraving of Mrs. Evelyn Ern, all working together as a team.

One of the remarkable features of good case hardening is its successful coloring. In this case beauty is joined with utility: The surface of a color case hardened lock is long wearing and resistant to the different influences in its daily use. The coal used and the temperature applied for case hardening is important for the success. By practising this work for many years, Max Ern knows how these go together perfectly. In his workshop even old Mauser actions are re-hardened. The greatest difficulty is, to avoid possible warping of the piece. Since the different thickness and the composition of the material used on the older gun parts is not known, warping is difficult to anticipate.

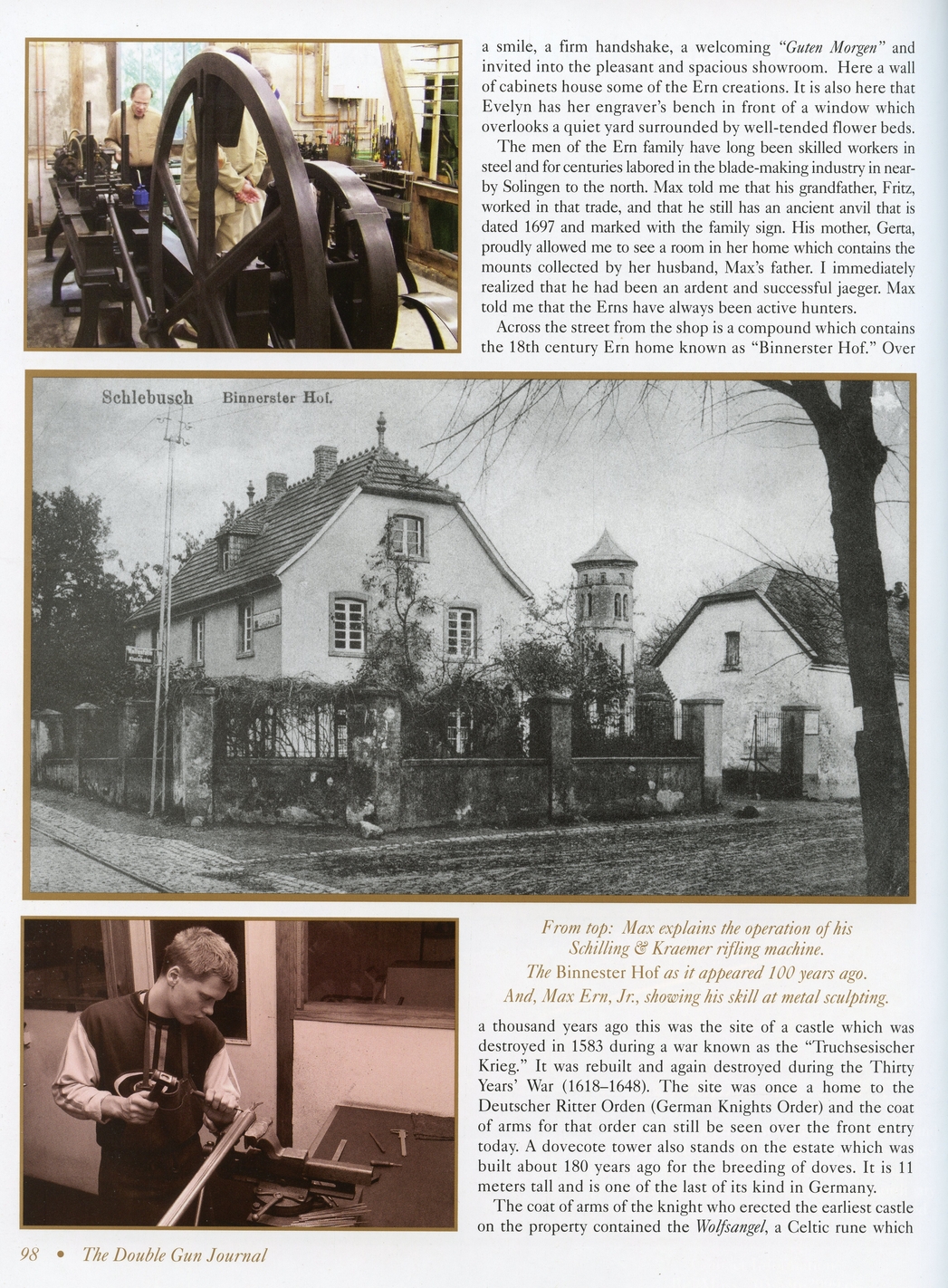

The Ern family has its origin in Solingen and was for centuries closely connected with the making of knife blades and the finishing of steel. Bennerston Hof, domicile of the Ern family for centuries, has a wolf’s jaw on its coat of arms. The wolf’s jaw became a runic symbol for hunting and now becomes a symbol for modern hunting guns made with old and new proven techniques.

I wish to thank Clair Kofoed and the magazine Shooting Sportsman for the following article. Click below to open the PDF file

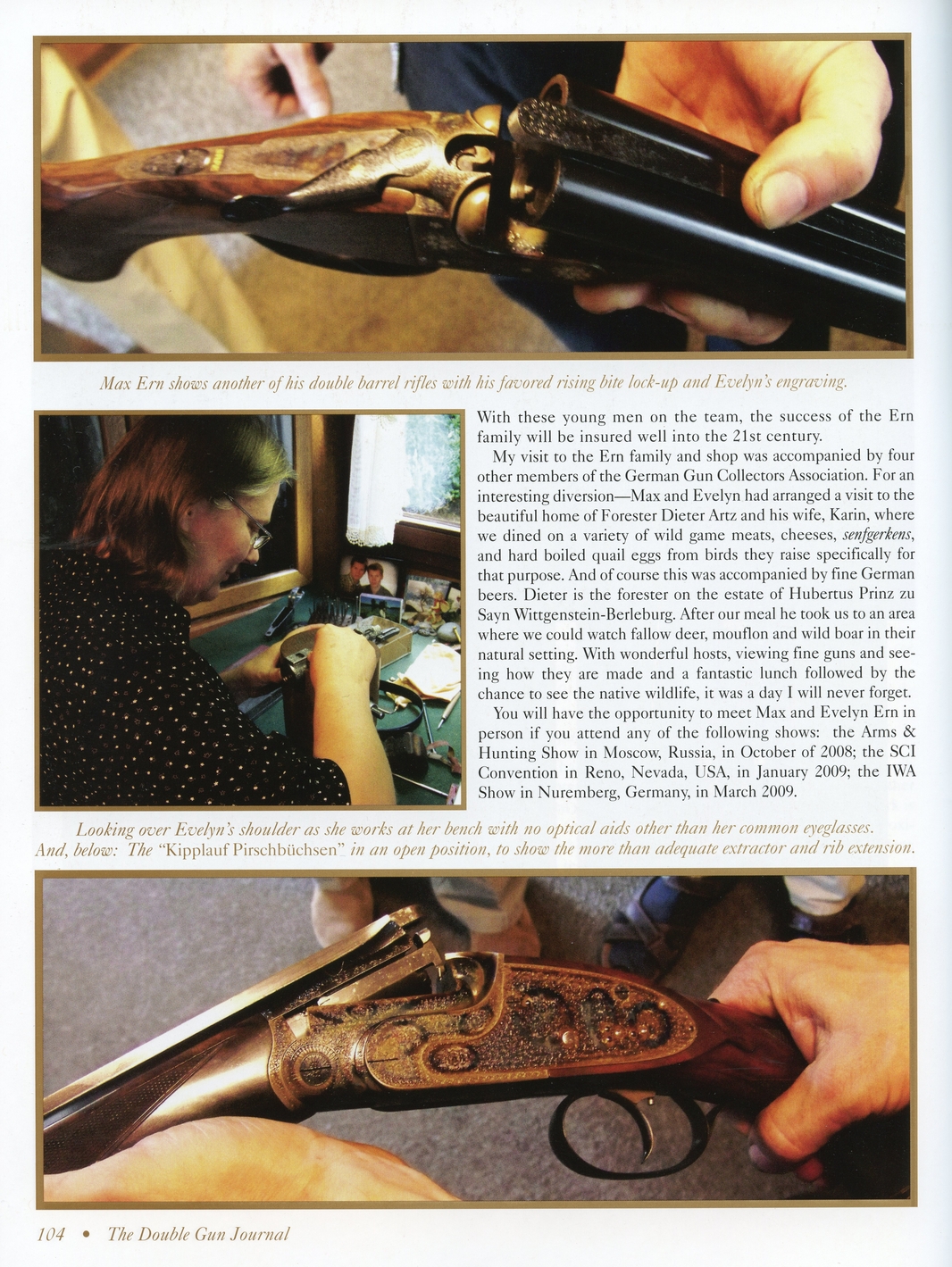

The following are views of some of Max and Evelyn’s work.

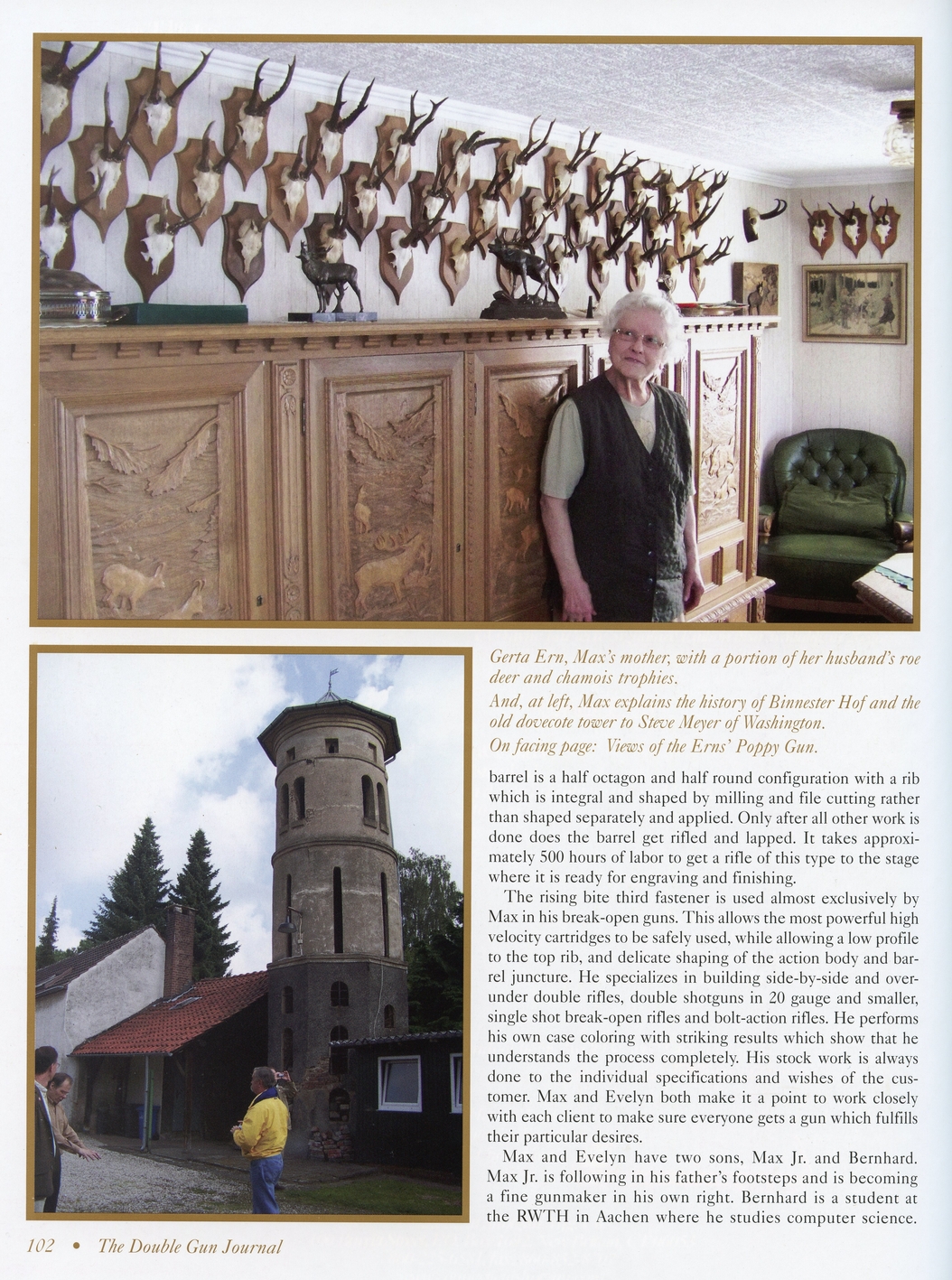

Here are some views of the Ern work shop.

Here are views of Max’s Machine Shop.

Max’s surface grinder, note the clean and neat building.

Max has embraced the computer age with this CNC machine

Max on the left coaches John Spencer on the Mann & Schlegelmilch (manufactured in Neundorf) barrel straightening machine while john Laborde looks on.

Max explains his barrel honing machine

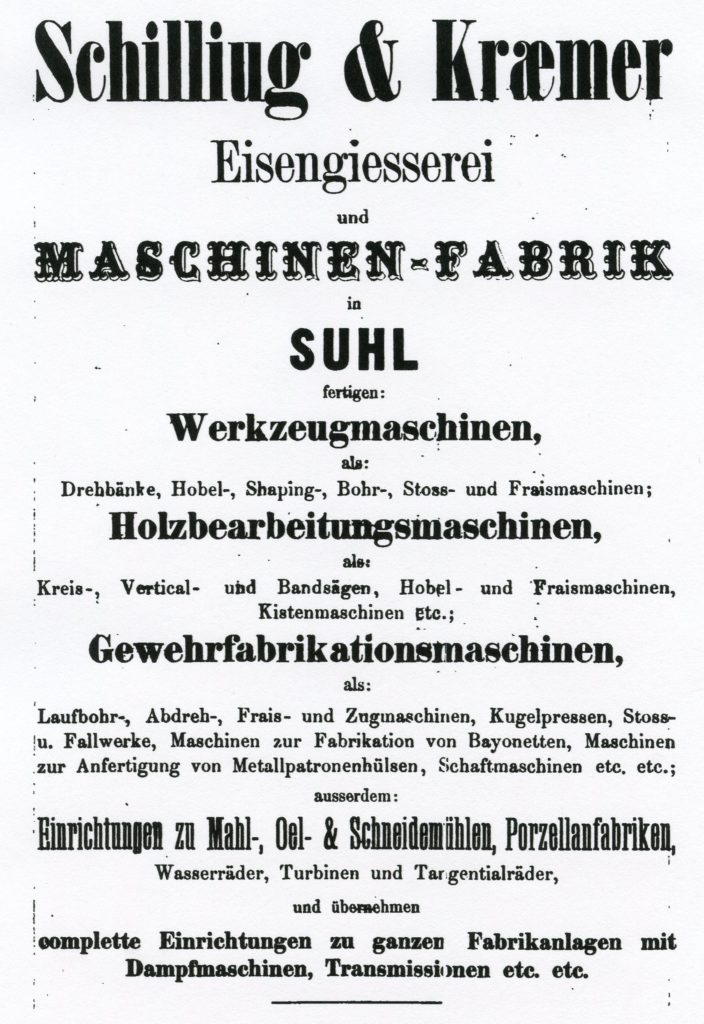

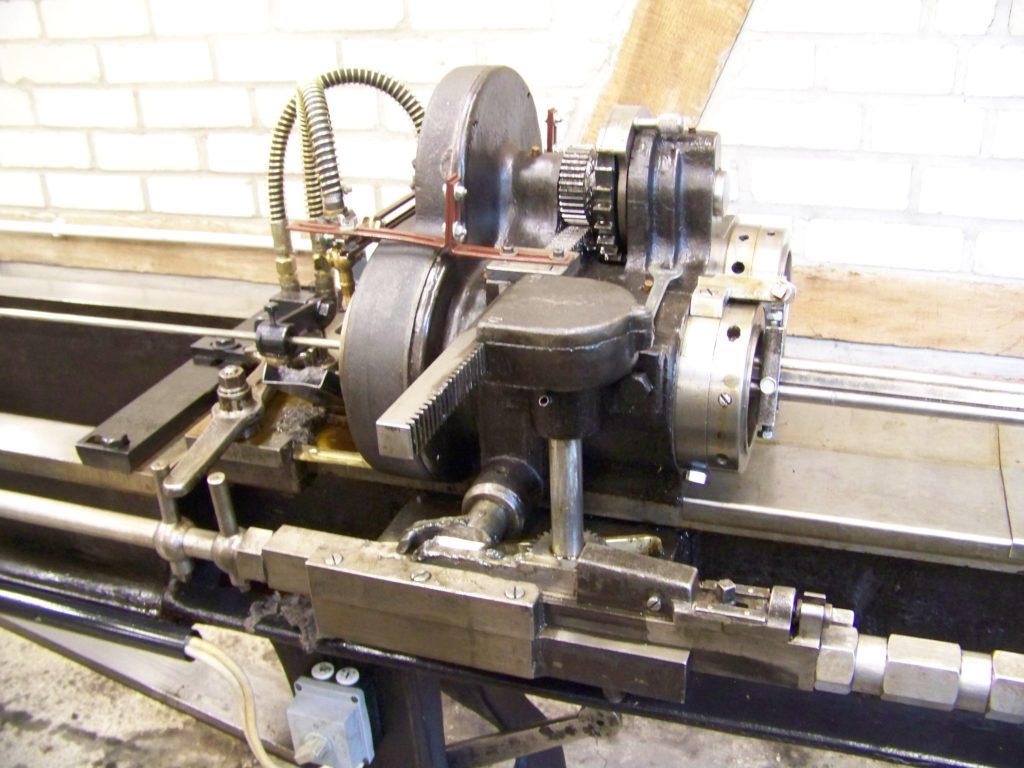

Max explains the history of his Schilling & Kraemer rifling machine manufactured in Suhl.

Above: an advertisement from the 1873 Handbuch der Leistungsfähigkeit der gesammten Industrie for the Schilling & Kraemer firm.

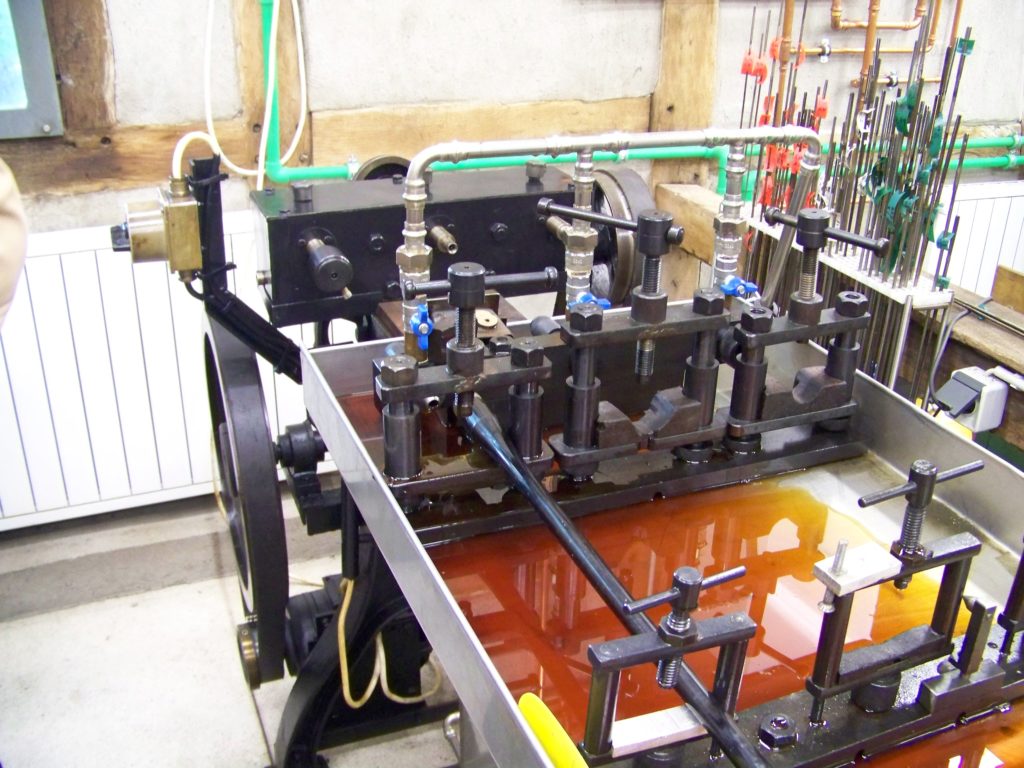

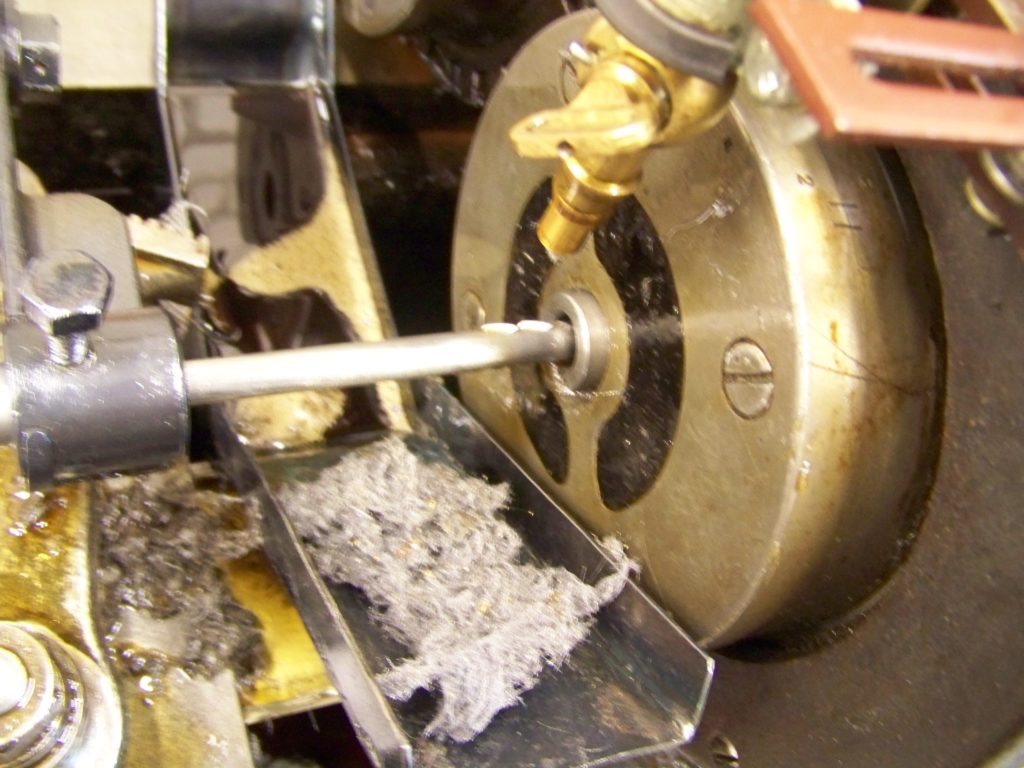

Max’s barrel lapping machine.